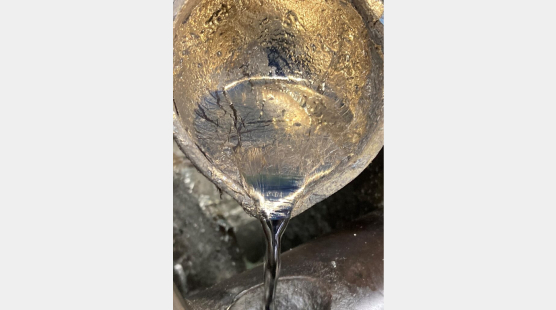

Static & Centrifugal Casting

Using on-site equipment, we centrifugally and statically cast Babbitt for many types of Babbitt bearing designs. We are experienced in casting Babbitt into shell materials such as steel, bronze, cast iron, and copper. We cast commonly available ASTM B23 Alloy Grade 1, Grade 2, Grade 3, and Grade 11 Babbitt, as well as other Babbitt formulations based on customers’ needs.

Precision CNC Machining

Jensen Machine’s superior CNC machining service delivers quality results for a wide variety of applications, and serves the needs of major industries including oil & gas, power generation, aerospace, and beyond.

Our advanced machinery includes CNC turning and milling centers, as well as manual equipment. We have the capability for CAD-CAM programming. Special tooling and fixtures are designed and manufactured in-house to reduce lead time. In fact, nearly 100% of our manufacturing is performed in house, providing us control over the quality and lead times of all our products.

We offer reverse engineering services. Provide us a known good Babbitt bearing and we can replicate it.

Inspection & Quality Assurance

As an ISO 9001 registered company, we are committed to producing quality parts.

From dye penetrant to ultrasonic inspection, we offer documented inspection and testing of Babbitt bearings and seals. For parts that have testing requirements or specific certifications that are beyond our capabilities, we have relationships with outside testing vendors to meet your requirements.

Using our in-house CMM or other measurement methods, we can provide dimensional inspection reports upon request.

Legacy Part Conversion

Every industry has the challenge of dealing with parts that need replacement, but are from a previous generation of older machinery. The designs may be based on older, antiquated manufacturing methods of that time. Casting patterns may no longer be available. Extensive fixturing may be lost. Perhaps the supplier has closed and the knowledge and tooling to make the part is gone. For a variety of reasons, acquiring the original part manufactured in the original way may no longer be feasible.

We work with our customers to convert their legacy designs to create bearings or other parts made with modern methods from a readily available stock material, ensuring we meet the all the critical dimensions and function of the original design. Contact us to discuss how we can help you convert your legacy design.